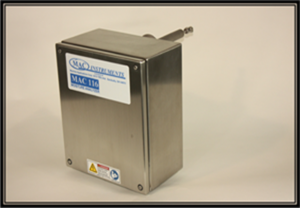

MAC 116 Steam Analyser

Application

Control flow of steam.

Description

This Analyser is typically used to control the flow of steam into the cooking atmosphere in order to maintain correct moisture levels for maximum product yield and minimum cooking time.

The increase in yield can quickly pay for the MAC116. In many installations, savings are also realized by a decrease in the amount of steam used. The MAC116 can also be used in the drying and pasteurizing of food products Specifically designed for use on continuous conveyor ovens that are used to cook meat and poultry, the MAC116 has been in use in the food industry since 2011. The MAC116 is successfully operating in a large number of cooking installations in many countries throughout the world.

The rugged design of the MAC116 allows wash down with the harsh chemicals that are used in sanitizing operations. The MAC116 incorporates a stainless steel enclosure that mounts to the oven using industry standard sanitary ferrules, a gasket, and a clamp. The stainless steel probe barrel is fully welded to ensure a sanitary installation.

The sampling port of the MAC116 projects through the oven wall where it samples the cooking atmosphere and measures its absolute moisture content in terms of % water vapor by volume.

A built in purge system allows the MAC116 to remain in place during clean in place (CIP) operations. The MAC116 is powered from a remote 24 volt DC power source in order to provide maximum safety in wet locations.

Features

- NEMA 4X / IP66 Waterproof Design

- Stainless steel enclosure and probe

- Mounts with standard sanitary fittings

- Purging for CIP process*

- Standard Signal Outputs

- Internal display and pushbuttons for diagnostics

- 24v DC powered for maximum safety